3 Ways To Extend The Life Of Manufacturing Equipment

In any industry that uses heavy machinery, including manufacturing, farming, mining, and more, keeping that machinery functioning properly for a long time is typically a high priority. Any breakdowns in equipment parts is costly for the business and you want everything to function well for the safety of your workers. Whether you're focusing on fin fan cleaning, frac tank cleaning, or heat exchanger cleaning, know these methods of keeping them around for years to come.

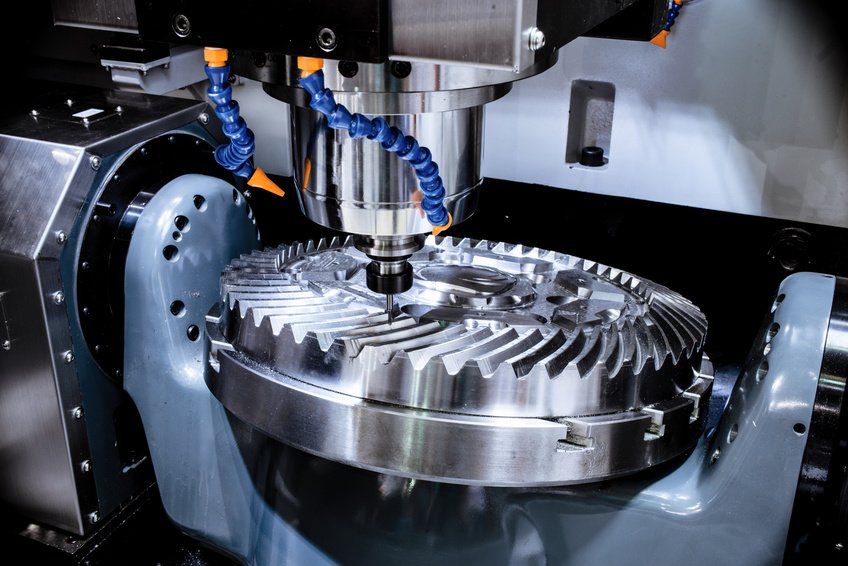

Check For Signs Of Wear

By spotting signs of wear early on, you'll be able to take steps to repair the equipment or replace it before it breaks down. Elements that contribute to equipment breakdown are high temperatures, vibration, shock, age, and friction. Of course, there will always be some vibration and frequent high temperatures when you're operating heavy machinery. Excessive amounts of either one can be very harmful to the equipment. Age will also come naturally, but it's important to monitor and replace equipment when needed.

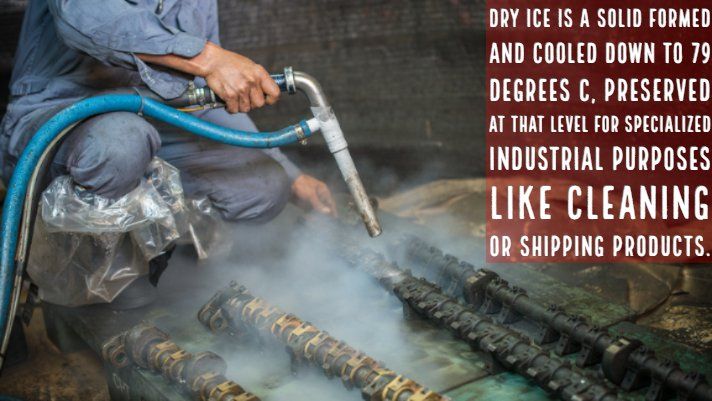

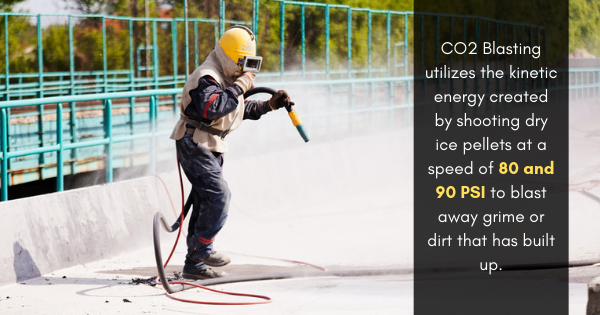

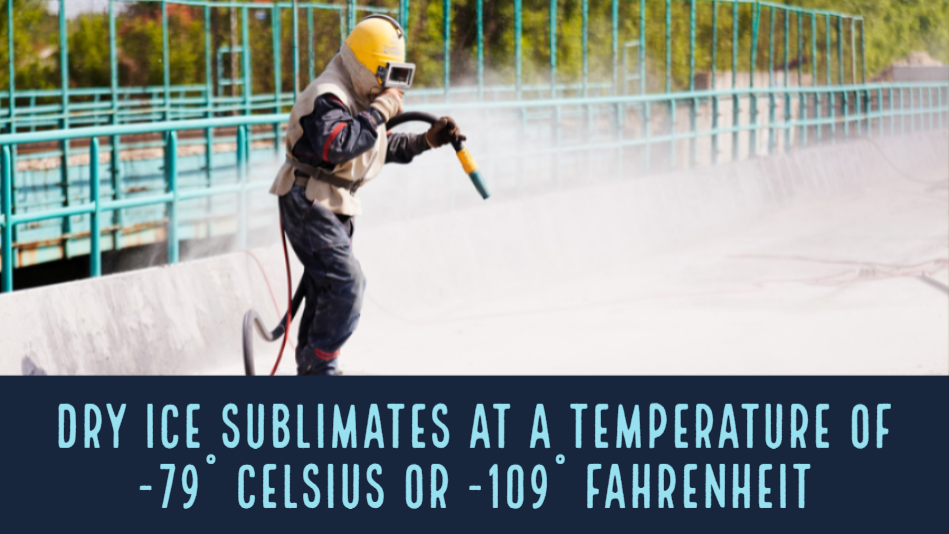

Use Dry Ice Blasting

When your equipment isn't clean, it will be more susceptible to wear and eventual breakdowns. The most effective method of cleaning heavy machinery and its parts is dry ice blasting. This cleaning method uses air compressed between 80 and 90 PSI that blasts pellets of dry ice at a high velocity to clean target surfaces. This is an effective method of heat exchanger and fin fan cleaningbecause of its ability to clean them without removing them from the larger machinery. Dry ice blasting is extremely effective in stripping away contaminants and leaving the surface spotless. It is also an environmentally-friendly cleaning solution, as it doesn't use any harmful chemicals, just pellets made of carbon dioxide.

Stay On Top Of Operator Training

| Poor operation of large machinery can easily lead to costly breakdowns and unsafe working conditions. These machines often have multiple operators, leaving even more opportunities for incorrect machine operation. Even employees who have been trained before should have regular check-ups, as anyone's skills can become rusty over time. Make sure that any operating manuals in your facility are up to date with the current procedures and that you trust your trainers to teach operators properly. Whether you contact an experienced professional for fin fan cleaning or retrain your operators on a large piece of machinery, you're taking necessary steps to ensure the longevity of your valuable equipment. These steps will not only guarantee the quality of your equipment parts, but your entire business as well. |