Be Aware of These 3 Common Types of Food Contamination

Any business in the restaurant industry needs to follow specific rules and regulations in order to keep dangerous contaminants away from their products. Before fighting these microscopic dangers with industrial cleaning methods, you need to know what they are. The hazards or contaminants that make food unsafe can be categorized into three main groups: biological (microorganisms), chemical (cleaning solvents and pest control), and physical (hair, dirt, and other matter).

Biological Contamination

A common cause of food poisoning and spoilage, biological contamination occurs when bacteria or toxins contaminate food. Bacteria are small microorganisms that split and multiply quickly. As they multiply they can latch on to food products, and when someone consumes the food they can quickly fall ill from the bacteria. Some bacteria are extremely toxic by themselves, such as salmonella, staphylococcus, and listeria. The process of bacteria multiplying and producing waste can sometimes be the cause of a consumer's illness rather than the bacteria themselves. Bacteria are impossible to see with the naked eye, but they commonly grow on raw meat, the human body, dust, kitchen cloths, food handlers' clothing, pets and pests, and even the air.

Chemical Contamination

When food comes in contact with chemicals, it can lead to chemical food poisoning. This type of contamination is easily preventable by using proper industrial cleaningtechniques and staying aware of these common sources:

- Kitchen cleaning agents. Do not keep food stored in the same place as your chemical cleaning solution. When you store them in close proximity you give the harmful chemicals an easy entry point to the food. Always use cleaning products that are specifically designed for kitchen use.

- Pest control products. Although you don't want pests getting to your food products either, be careful about getting pest prevention chemicals near the food. Products such as fly spray and rat poison are very hazardous if consumed.

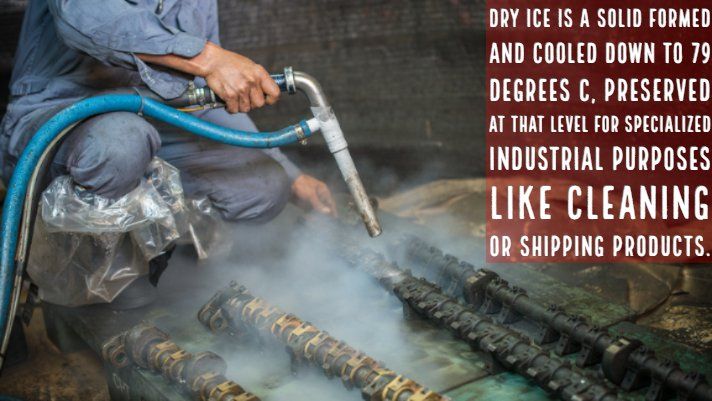

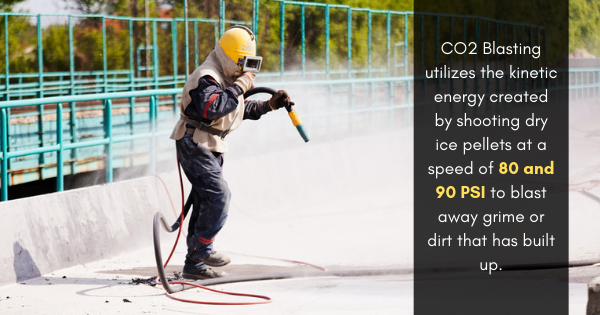

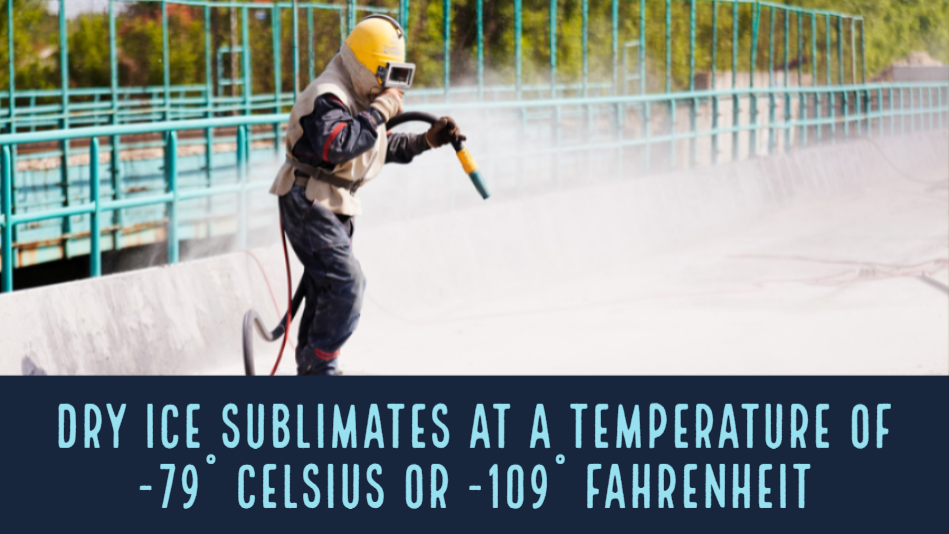

- Chemicals used in equipment maintenance. Kitchen machines and equipment with moving parts, such as slicers and mixers, may need regular oiling to keep working well. Use food-safe oil that won't contaminate the food that you prepare with the equipment. This equipment also needs to be cleaned so that bacteria doesn't grow. The most sanitary way to clean them is with dry ice cleaning services.

Physical Contamination

This type of contamination occurs when actual objects contaminate foods. It can also cross into biological contamination as bacteria can be transferred to food on hair strands or fingernails. These are two common sources of physical contamination, so be sure to always tie back hair, wear a hair net when possible, keep nails short and clean, and avoid wearing fake nails that can easily fall off. Physical contamination can also happen when pests, such as mice, rats, or cockroaches, leave droppings in the vicinity of the food. Although dirt is hard to notice in some foods, it can cause contamination when fruit and vegetables go unwashed.

Your restaurant's kitchen should be sanitized to perfection in order to ensure the health and safety of your guests. Stay vigilant about these types of contamination, and engage in regular industrial cleaning, like dry ice blasting, to properly clean every surface in your kitchen.