Slabs vs Pellets: How to Get the Most Out of Your Dry Ice

Your machinery needs the best cleaning on the market, and we believe dry ice blasting is the best way to do it. In order to get the most for your money, it's important to learn the ins and outs of dry ice production and storage.

How is dry ice produced?

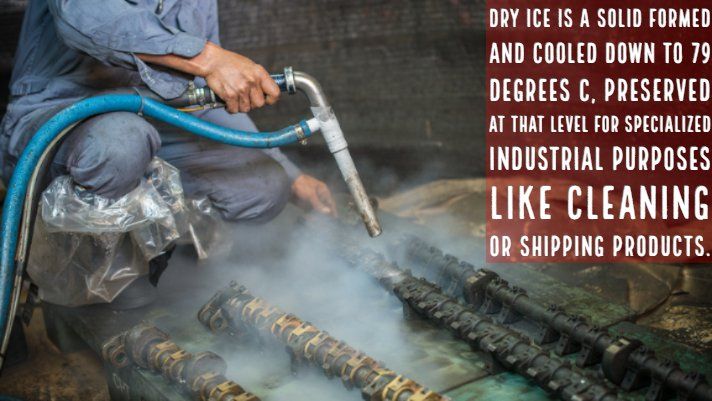

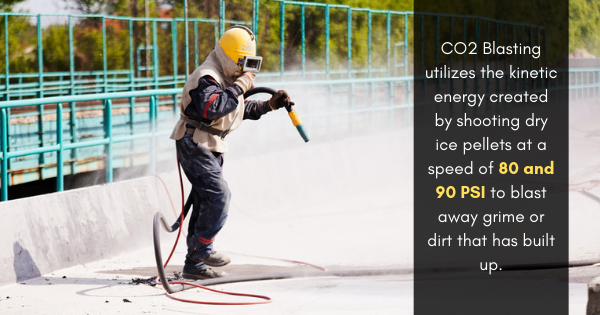

Dry ice is made from liquid carbon dioxide that has been pressed into pellets or slabs for various uses. When you use it to clean your machinery or industrial surfaces, the pellets are rapidly heated to sublimate the material. The resulting gas is then pressurized to provide dry ice cleaning solution. It will bombard your machinery, removing dirt and other foreign matter at a high pressure. It's an environmentally-friendly alternative to chemical cleaning.

Dry Ice Pellets

Storing your dry ice as pellets is the easiest way to use it as a cleaner. These small pellets are only the size of grains of rice. They are great for quick sublimation when you're ready to clean your machinery. They work best when applied across short distances for a short amount of time since they sublimate at a quicker rate. This is because of the larger surface area exposed to the air, causing the material to sublimate faster. This is the best option for cleaning your machinery.

Dry Ice Slabs

Slabs are larger pieces of dry iced compressed into a brick-like structure. This is a good option if you're buying your dry ice from a location that's further away, or if you're not going to use your dry ice right away. These work best for airline industries for cooling goods that are shipped long distances. If you order a slab of dry ice, consider taking it to your local processor for application processes.

Safety precautions

Dry ice is an incredibly cold material that can cause serious damage when it is exposed to skin. Always wear gloves and protective outer layers to prevent frostbite.