5 Industries That Can Use Dry Ice Blasting

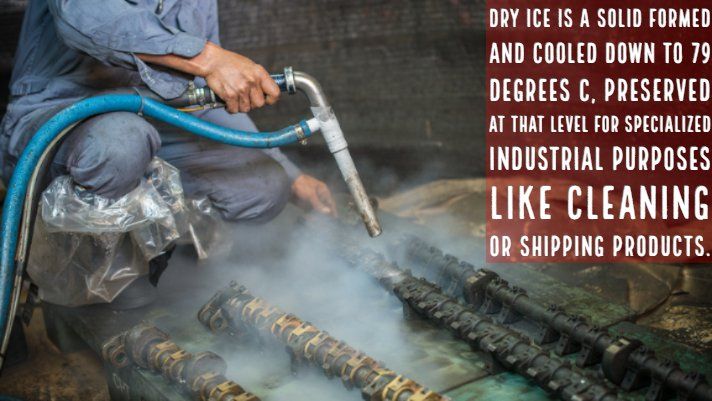

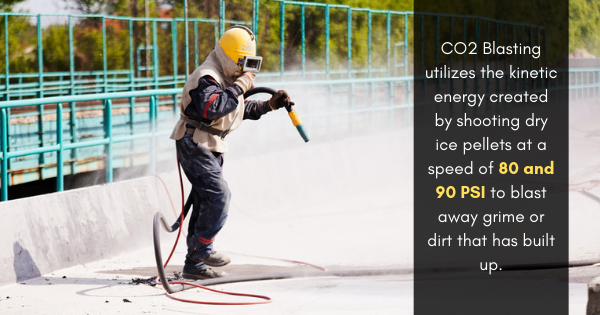

The modern world is made up of industries with complicated machinery and potentially hazardous material that cannot be cleaned using standard methods. Dry ice blastingis a cleaning method that efficient, safe, non-abrasive, economically friendly, and is FDA approved. The process uses air compressed between 80 and 90 PSI to shoot pellets of dry ice at high velocity. These pellets can clean a wide variety of targeted surfaces and serve many different industries. If you think your industry could benefit from dry ice cleaning systems, check the list below for its many applications.

- Food Processing Industry

Any businesses in the food industry face the challenge of cleaning regularly to eliminate harmful bacteria and cleaning with solutions that are safe for the machinery. Ice pellets are from frozen carbon dioxide gas, which will not contaminate food, cooking surfaces, or equipment. Dry ice blasting sanitizes as it cleans and will remove dirt, grease, coatings, and food residue from all food service equipment. - Automotive Industry

With the amount of work that equipment in the automotive industry has to do, parts get dirty very quickly. Traditional cleaning may require downtime, but dry ice cleaning can be done while lines are fully operational. The method is very effective at cleaning weld lines, electronics, wiring, tools, and presses. - Printing Industry

When using printing presses, it is important to keep the parts free of any foreign materials. By using dry ice blasting, printers can improve print quality, reduce scrap rates, and extend the life of printing press parts. Dry ice blasting cleans off ink and paper pulp build up, grease, and oils without having the disassemble the press. - Aerospace Industry

Cleaning aerospace facilities and equipment can be difficult, as they are electrically charged environments. Frozen carbon dioxide does not conduct electricity because it is a gas, making dry ice cleaning safe for employees. The innovative method cleans foam insulation, coatings, controls, and aviation grease that builds up over time. - Oil Industry

As apparent in the other industries, dry ice cleaning is very effective at cleaning off oil. In oil field and petroleum operations, the equipment needs to be cleaned regularly to ensure the safety of the employees and of the site. Dry ice blast cleaning can rid the slippery equipment of acids, bitumen, and chemicals. This process protects the equipment from corrosion and can be done while the machinery is running.

Using dry ice cleaning is a smart decision for anyone in any of these industries. Many more field that deal with hefty equipment are also prime subjects for dry ice cleaning, so contact a cleaner today to find out if it is right for your business.