Why Frac Pump Radiator Cleaning Is Important

Frac pumps take a large amount of damage and abuse daily. To mitigate the damages your frac pump absorbs, you need to make sure it is regularly cleaned. Clean frac pumps ensure the safety of operators in the field and increase the longevity of the pumps themselves. The frac pump radiator is an essential part of the machine that needs to remain clean. While the logistics of frac pump radiator cleaning can seem daunting, there are simple maintenance methods that you can adopt to make it simpler.

Why You Need Regular Frac Pump Radiator Cleaning

The frac pump radiator is essential in keeping equipment cooled and performing at an optimum level. When the radiator fails, the rest of the equipment experiences overheating. Failure often results from unclean radiators as foreign materials build up and interrupt the operation of the radiator. When the radiator is clean, the machine consistently produces desired results, boosting your business and eliminating emergency maintenance costs. In contrast, preventative maintenance will always save money and time in the long run. Ignoring problems with frac pump radiators will only allow them to worsen over time and eventually shut down the operation.

Your Frac Pump Maintenance Guidelines

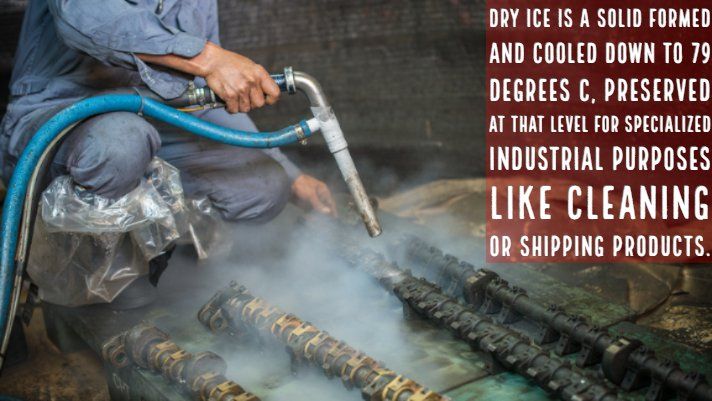

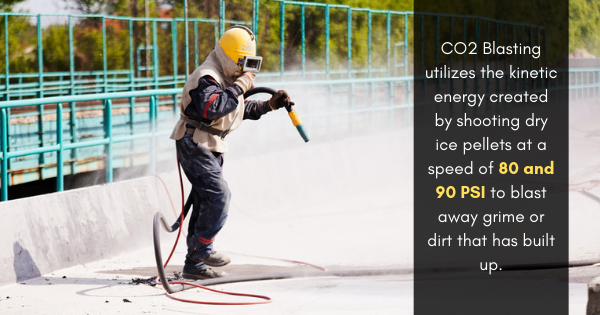

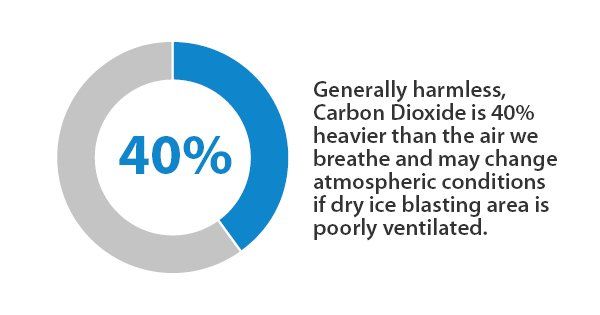

Maintenance programs in any field need the proper tools, methods, and training to succeed. Those in charge of frac pump maintenance should first consult the instructions of the pump manufacturer. Then, they should create a pump maintenance schedule and a parts list. Their guidelines should include information on each power end and fluid end that an operator of the pump may encounter. For tricky jobs like the frac pump radiator cleaning, maintenance managers can turn to dry ice cleaning systems. Dry ice blasting is effective at cleaning hefty pieces of machinery and can be done while the frac pump is running. Ensure that the dry ice blasting area is well-ventilated, as the carbon dioxide that makes the dry ice is 40% heavier than the air we breathe and may change atmospheric conditions.

In a business where broken equipment can cost thousands of dollars in repairs and lost time, preventative cleaning is a lifesaver. By using dry ice blasting for your frac pump radiator, you'll keep your equipment running efficiently and your employees safe.